Built in 1960, Catholic University of America’s Seton Hall is a 5-story mid-rise building with an extensive granite facade. The building houses administrative offices, classrooms, student dormitories, and an ornately handcrafted chapel.

The original building envelope was designed as a barrier wall with no drain cavity or working flashing system. The structure’s exterior wall cladding is composed of large granite panels independently supported by metal components and anchors.

Project Overview

Built in 1960, Catholic University of America’s Seton Hall is a 5-story mid-rise building with an extensive granite facade. The building houses administrative offices, classrooms, student dormitories, and an ornately handcrafted chapel.

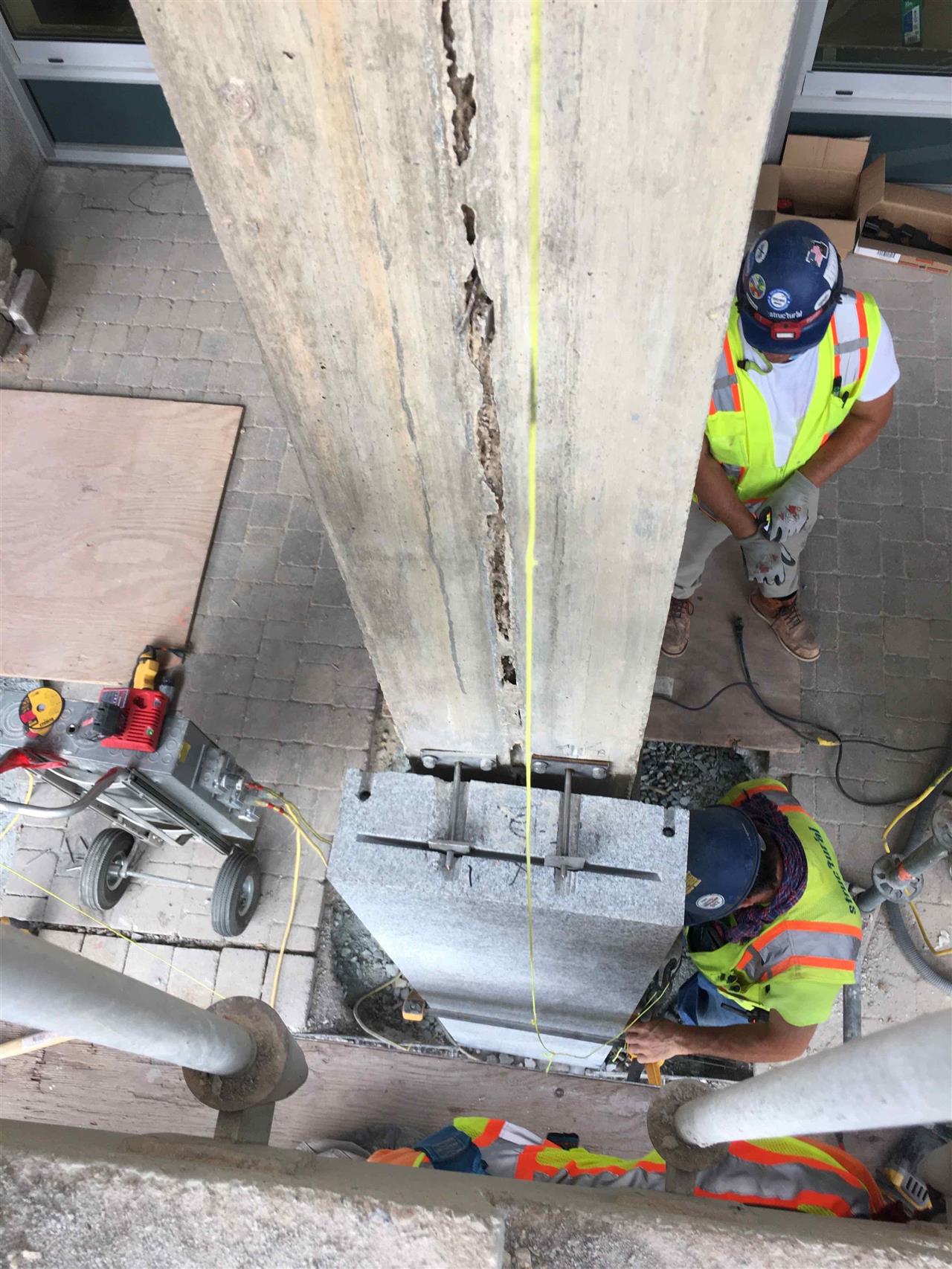

The original building envelope was designed as a barrier wall with no drain cavity or working flashing system. The structure’s exterior wall cladding is composed of large granite panels independently supported by metal components and anchors. When spalling of the granite panels was discovered, the owner sought repairs. Temporary anchors were installed to stabilize panels on the South and East façade. However, after a seismic event, the granite panels became an increased safety risk for those accessing the campus building.

STRUCTURAL supported Simpson Gumpertz & Heger (SGH), in completing an investigation of the building and found that both temporary anchors and the existing shelf angle showed signs of significant corrosion. After investigating the structure, the Owner brought together a design-build team to complete the repairs to the building’s façade.

The project scope included removing and replacing the granite panels and shelf angles, installing new flashing, and providing a new air barrier system. In addition, STRUCTURAL provided scaffold access, repaired caulked and sealed joints, and replaced windows. The team was later asked to repair the existing brick back-up wall as well as existing concrete columns.

Using sledgehammers, crews demolished 708 pieces of granite approximately 81 tons. However, during demolition, the team discovered differing site dimensions. To address the newly discovered conditions, STRUCTURAL phased the back-up wall repairs. The team utilized an anchorage system, a hand-set method in which each stone is individually attached to the building’s primary structure as opposed to a panelized system in which panels would be installed onto a frame. Other challenges the team overcame included sourcing limitations for granite, and color matching the new granite to the existing panels. The team submitted over 15 different colors from 8 different suppliers and was able to gain approval for the granite color match.

The work scope had to be completed before students moved in, leaving a 21-week schedule during the height of a pandemic. The project was successfully completed per the owner’s schedule and without safety incidents.

PROJECT INFO

- Location: Washington, DC

- Specialty Contractor: STRUCTURAL

- General Contractor: Patner Construction

- Engineer of Record: Simpson Gumpertz & Heger (SGH)

SOLUTIONS

MARKET

Related Projects

Contact Us

Ready to take the next step? Reach out to our team today and let’s work together on solutions to your infrastructure challenges.